The Hot Stamping Process

Hot stamping is a straight forward process:

1) A die is mounted and heated

2) Foil is positioned above the material to be imprinted

3) A combination of heat, dwell time, pressure and stripping time control the quality of the stamp. Foil stamping is environmentally friendly due to it being a dry process. It does not use solvents or inks and does not create any harmful vapors.

A successful hot stamping job is directly related to the quality of the original artwork. In order to insure the highest quality reproduction of an imprint, the original artwork should be “camera-ready.” The better the artwork at the beginning, the better the imprint reproduction result. The key to a successful hot stamping job is three-fold; the first is creating a fixture to support the part firmly under the decorating area. Second, the fixture must also position the part for repeatability of the graphic location. And third, the fixture must allow the operator to easily load and unload the part from the fixture.

Components of the Hot Stamping Process

ANVIL usually made of a hard rubber or phenolic

FOIL ROLL LEAF is the ink of a hot stamping operation. It is made up of a carrier with a series of coatings to be transferred.

SUBSTRATE a wide variety of substrates is suitable for the hot stamping process. Surface tension of the substrate has the same affect on hot stamping as it does on printing

HOT STAMPING DIE the hot stamp die is an engraved plate where the non-printing areas are relieved.

HEAT + PRESSURE + TIME = FOIL TRANSFER Foil is transferred to the substrate when a heated die forces the foil onto the substrate against the anvil.

A) Small and Medium sized production and substrates:- Principles are:

1. Flat Foil Stamping

2. Sculpted Foil Stamping (Multi-Level Foil Stamping)

3. Vertical Foil Stamping a maximum of 90 degrees

4. Peripheral Foil Stamping entire 360 degrees

– Machines are: 1. Hand-operated Foil Stamping Machine 2. Pneumatic Foil Stamping Machine 3. Foil Fuser Machines

B) Large sized production – Principles are:

1. Flat-Flat Principle

2. Round-On-Flat Principle

3. Round-On-Round Principle

– Machines are: Categorized to web and sheet fed stamping or embossing machine

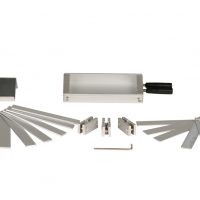

ROTARY HOT STAMPING Short dwell time is also the reason rotary hot stamping is able to produce a greater level of detail than the best flat bed equipment. ROTARY HOT STAMP EQUIPMENT First it must maintain the desired temperature of the die. Second it must hold the die securely in position to produce even depth of impression through heavy and light coverage regions of the die. TEMPERATURE CONTROL IMPRESSION CONTROL The second task of any rotary hot stamping system is that it maintains an even depth of impression.

Die materials are divided in to metal and silicon rubber dies in which four metal materials are most often used for die construction: magnesium, copper, steel and brass. The material used for a specific application depends upon a number of factors Tooling is CNC engraving Silicon they will conform much better to parts that are not perfectly flat

Types of Dies

1. Single-Level straight and level

2. Multilevel distinct levels of depth are used to add a variance in dimension to the image

3. Round Edge provides a soft edge effect rather than a hard ruled edge.

4. Beveled Edge provides the appearance of combining the softness of a round edge with the well defined lines of a distinct edge

5. Sculptured a hand-tooled die

6. Rotary Die Cylinders